Alternate Energy Systems, Inc. manufactures a complete line of LPG-air blending and mixing systems, ranging in capacities from 7MM BTU to over 1,000MM BTU per hour.

Our complete line of venturi mixers and piston operated blenders utilize the finest quality material and knowledge to meet the requirements of commercial, industrial, and natural gas utility customers around the world.

The terms "mixer" and "blender" are used interchangeably on this page. Both describe a device which is used to mix two gases at preset or variable ratios. The majority of applications will be for simulating natural gas with a mixture of LPG vapor and air, so that the mixture becomes directly compatible and interchangeable with natural gas. Other applications include the "conditioning", or "stabilization", of natural gas, in order to produce gas with constant calorific properties, which is essential for many industrial processes.

There are several methods to mix air and LPG vapor, but probably the most simple is by using a venturi-type mixer, consisting of a venturi-tube and a venturi- nozzle. This method, as well as other methods, holds very accurate air-to-fuel ratios through a narrow range. This type mixer does not generally require compressed air for operation. The mixture of air/vapor is fed into a surge tank, where it is maintained at a set pressure, and then drawn from the surge tank for use. This type system is only recommended for intermittent periods of use and is simple to install, operate, and maintain.

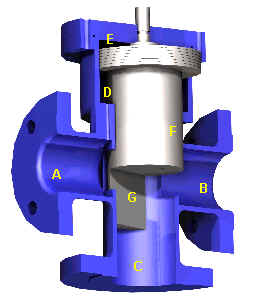

For larger system capacities, or for higher system pressures, AES has developed, and received national and international patents for, a Piston Operated Mixer (POM). This mixer utilizes very simple, yet extremely effective components, making this mixer the easiest to operate, most reliable, easiest to control, and most stable mixer on the market today. It combines the advantages of "floating orifice" type mixers and "proportional blenders" in one compact unit.

Regardless of the type vaporizer and mixer, a standby system can be designed for the requirements of a small user, and equally well for the requirements of large industrial and utility users. It can also be equipped with a variety of options and accessories, including fully automatic gas properties control, integration into Plant Control and Monitoring Systems, and Remote Monitoring and Operation.

In times of uncertain oil prices and supplies, a standby system should be considered by all natural gas users. A simple analogy is that - we keep a spare tire for our automobile in the event of a flat - a standby system is a spare fuel supply in the event natural gas is interrupted or demand cannot be met.

For most users, however, standby systems for natural gas offer the opportunity to take advantage of steep discounts their gas utilities offer to customers who switch to an "interruptible rate". To learn more about interruptible rates and how they can pay for a standby system in very short periods of time, and thereafter continuously contribute to "the bottom line" of business, call Alternate Energy Systems at +1 770 487 8596.

Click on the pictures to go to the page for that type mixer.

Capacities from 20 MMBTU/hr to over 1,000 MMBTU/hr