Downloads

General Information

Water Bath Vaporizers use - as the name implies - water as the heat transfer medium. However, since the heat exchanger components and the bath box of the WB-series are manufactured from carbon steel, it is recommended that the heat transfer solution be a mixture of water and an industrial coolant/heat transfer fluid with inhibitors to provide rust/corrosion protection.

Under no circumstances should an automotive grade coolant or antifreeze be used as the heat transfer fluid. Using standard automotive coolant could cause premature deterioration of the heat exchangers and other vaporizer components.

It is also recommended that the water in the heat transfer solutions be de-ionized. While it is acceptable to use small amounts of standard tap-water to replenish any water that might have evaporated, it is not recommended to use standard tap-water for the initial charge of the water bath. If at all possible, topping-off should be done with pre-diluted solutions of corrosion-inhibited heat transfer solution at the required system concentration (see water specifications below).

Heat Transfer Solution recommended by Alternate Energy Systems

Industrial-grade heat transfer solutions are usually Ethylene-Glycol or Propylene-Glycol based. Both types have comparable heat transfer capabilities, almost identical freeze protection, and, if used with inhibitors, can provide excellent corrosion protection.

Propylene-Glycol based heat transfer fluids, while slightly more expensive than Ethylene-Glycol based solutions, are by far more environmentally friendly, and are therefore the only heat transfer solutions recommended by Alternate Energy Systems.

Alternate Energy Systems recommends a 50/50 Propylene-Glycol/DI-Water solution for installations in all locations without extreme ambient temperatures. This mixture will provide burst protection to -60°F (-50°C), and will provide freeze protection to -30°F (-34°C), while providing maximum corrosion protection. Specially formulated ProCool™ heat transfer fluid is available for installations with extremely low or extremely high ambient temperatures.

In cooperation with a leading manufacturer of corrosion-inhibited Propylene-Glycol, Alternate Energy Systems offers ProCool™ heat transfer fluid for all WB-series Water Bath Vaporizers.

We are stocking ProCool™-50 (pre-mixed 50/50 with DI-Water), in 55-gallon drums and in 275-gallon totes, and can ship the quantities needed for the initial charge on the same truck as the vaporizer at no, or very minimal, additional shipping charges.

If required, we can also provide a small utility pump, complete with suction hose and discharge hose, for the transfer of the ProCool™ heat transfer fluid from the drums or totes to the vaporizer.

10-Year Warranty for Heat Exchangers

Alternate Energy Systems extends a limited 10-year warranty for heat exchangers to all customers who purchase ProCool™ heat transfer solution for the initial charge of the vaporizer bath and who can document that recommended maintenance procedures, including periodic testing and, if required, re-inhibiting, have been followed.

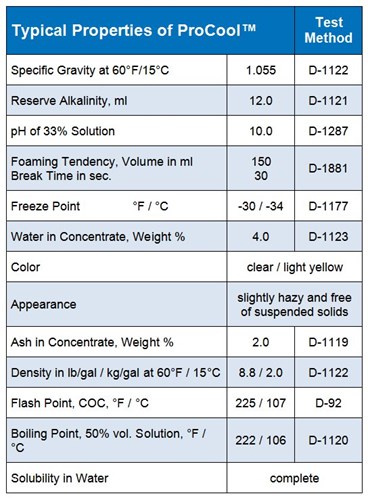

ProCool™ Heat Transfer Fluid (manufactured for Alternate Energy Systems, Inc.)

ProCool™ heat transfer fluid is an inhibited propylene glycol based industrial heat transfer agent. It is a slightly hazy liquid, free of suspended solids with only a slight odor.

Since ProCool™ heat transfer fluid is formulated with propylene glycol, it is especially suitable for applications in which toxicological and environmental considerations are critical.

ProCool™ heat transfer fluid is compatible and completely interchangeable with systems currently utilizing ethylene glycol based heat transfer agents.

ProCool™ heat transfer fluid protects heat exchanger systems from freezing in winter, overheating in summer, and corrosion in all seasons.

Improved heat transfer and less internal corrosion contributes significantly to lower overall operating and maintenance costs.

ProCool™ heat transfer fluid is recommended as a heat transfer fluid for vaporizers. The corrosion protection provided by ProCool™ heat transfer fluid and its low toxicity level as compared to other heat transfer fluids makes it an ideal transfer medium.

Water Specifications

| Component | Specification |

| Chloride | 25 ppm max. |

| Sulfate | 25 ppm max. |

| Calcium | 25 ppm max. |

| Magnesium | 25 ppm max. |

| Total Hardness | 100 ppm max. |

To avoid the introduction of water with questionable quality, Alternate Energy Systems recommends to use only pre-diluted ProCool™ heat transfer fluid, and to top off with deionized/distilled Water.

Heat Transfer Solution Maintenance

Alternate Energy Systems, through an independent laboratory, provides a comprehensive system maintenance program, including a product analysis service to assure that the heat transfer solution maintains the proper inhibitor level and desired freeze protection.

Once the system is in operation, it is recommended that samples of solution be taken at least once a year. The solution should be circulated for 30 minutes prior to sampling to ensure a representative sample.

Sample Test Kits

Sample test kits are available upon request from Alternate Energy Systems free of charge to customers who purchase ProCool™ heat transfer fluid products. The kits include: self-addressed shipping box; pre-labeled sample container; weather-proof self-adhesive product installation tag; and detailed sampling procedures. Analytical results from the samples will be forwarded by the laboratory directly to our customers.

Reinhibiting Procedure

Occasionally, after prolonged or severe service, a solution of ProCool™ heat transfer fluid may need to be reinhibited. The need for reinhibition will be detected during the periodic analysis program and a recommended procedure will be included with the analytical results.

ProCool™ heat transfer fluid supplemental coolant additives (SCA) are available in five gallon and 55-gallon drum quantities from Alternate Energy Systems.

The components of ProCool™ SCA replenish critical inhibitors that are required to provide continued protection. Additives used in inhibiting ProCool™ heat transfer fluid coolant should be handled in strict accordance with instructions that are included with the shipment.

Availability

ProCool™ heat transfer fluid is only available from Alternate Energy Systems, Inc. We stock ProCool™ heat transfer fluid in 55-gal drums and in 275-gal totes, and can ship the quantities needed for the initial charge on the same truck as the vaporizer at no, or very minimal, additional shipping charges.

If required, we can also provide a small utility pump, complete with suction hose and discharge hose, for the transfer of the ProCool™ heat transfer fluid from the drums or totes to the vaporizer.

Handling and Storage

ProCool™ heat transfer fluid may be stored in unlined carbon steel tanks and drums. If storage of concentrated ProCool™ heat transfer fluid for periods over 12 months is desired, it is recommended that the storage vessels be constructed from aluminum, stainless steel, or lined carbon steel. Vinyl, epoxy, and phenolic linings are suitable. Amercoat®-23 and Amercoat®-75 linings have been found to be satisfactory.

ProCool™ heat transfer fluid may be stored in unlined carbon steel tanks and drums. If storage of concentrated ProCool™ heat transfer fluid for periods over 12 months is desired, it is recommended that the storage vessels be constructed from aluminum, stainless steel, or lined carbon steel. Vinyl, epoxy, and phenolic linings are suitable. Amercoat®-23 and Amercoat®-75 linings have been found to be satisfactory.

ProCool™ heat transfer fluid in undiluted form will not freeze at ambient temperatures. Freezing will not harm ProCool™ heat transfer fluid, but when the temperature of undiluted ProCool™ heat transfer fluid is below 30°F, the viscosity will be such that pumping and transfer will be difficult. In areas where these conditions exist, it is recommended that storage vessels be equipped with stainless steel heating coils.

Diluted ProCool™ heat transfer fluid is easily pumped under normally expected temperatures. However, at temperatures below - 20°F, special pumping equipment may be necessary.

The normal precautions associated with any chemical should be observed in handling ProCool™ heat transfer fluid. This product is neither explosive nor flammable under normal storage conditions. The propylene glycol in this product is considered practically nontoxic. Splashes onto eyes or skin however, must be washed away quickly and medical treatment is advised for eye exposure. Breathing of the vapors or mists should be avoided. Consult the available MSDS for details.

Toxicity and Safety

ProCool™ heat transfer fluid is not considered hazardous under ordinary conditions of handling and use. Propylene glycol, which is the main component of this product, is considered practically nontoxic. ProCool™ heat transfer fluid is only minimally irritating to skin and eyes, but as with any chemical, unnecessary contact with these body parts is to be avoided. Click on this link to download the Material Safety Data Sheet for ProCool™ heat transfer fluid.

Additional Information

Additional information can be found in the ProCool™ Brochure, where we have concentrated data as it pertains to the ProCool™ product. A recommended Water Bath Vaporizer filling procedure is included in the same brochure. For all other information please contact Alternate Energy Systems, Inc.