Downloads

Pump System Features

- Capacities from 5 gpm to 150+ gpm

- Direct-Drive Turbine Pumps for small capacity

- Belt-Driven Sliding-Vane Pumps for large capacity

- Skid-mounted

- Primed and Painted (Marine Grade)

- Inlet Strainer

- Flexible Inlet/Outlet/Bypass Connections

- All-welded piping

- Backpressure Regulator

- Differential Pressure Regulator

- Summer-Bypass

- Liquid-filled Pressure Gauges

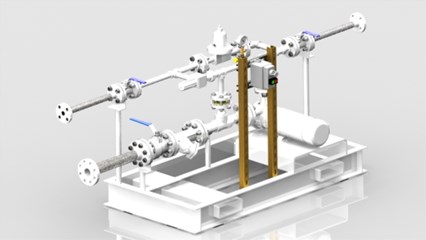

- Single-Pump Systems

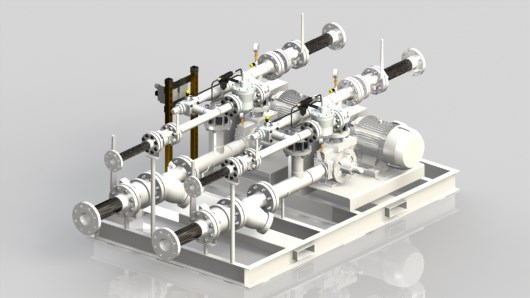

- Duplex-Pump Systems

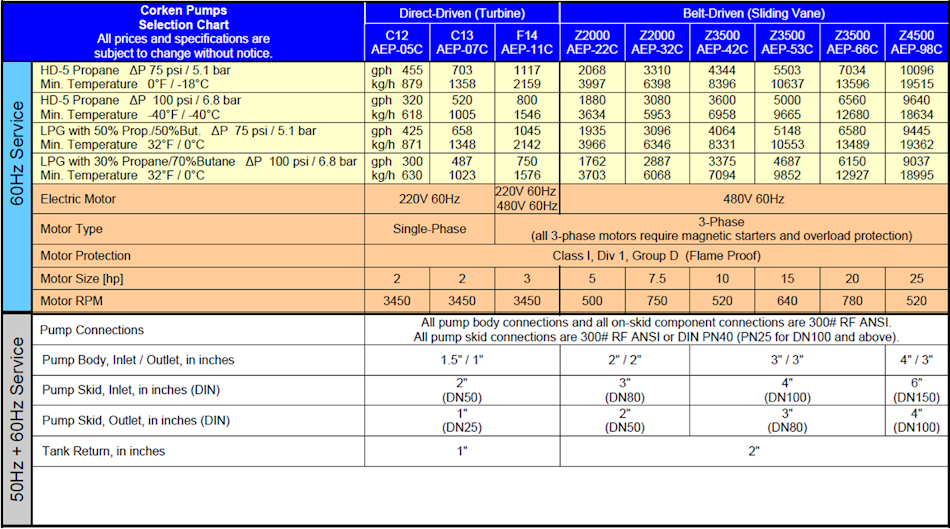

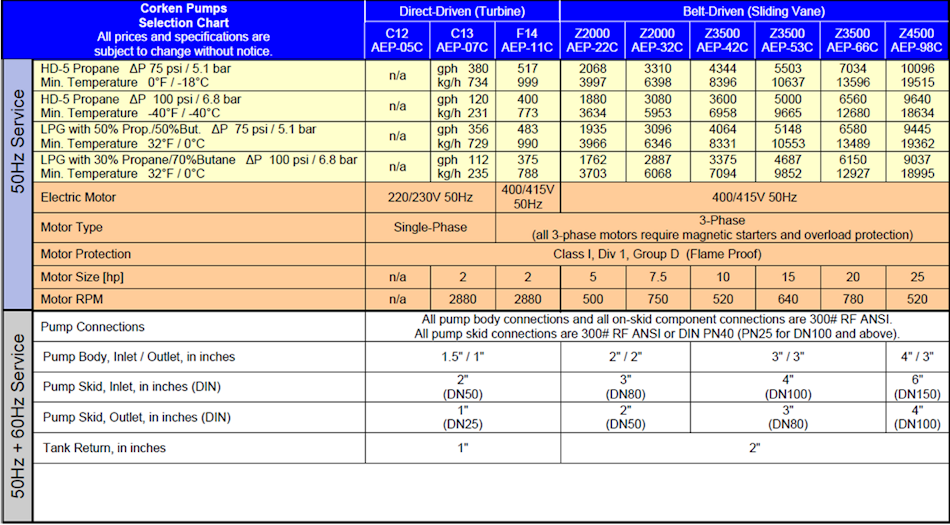

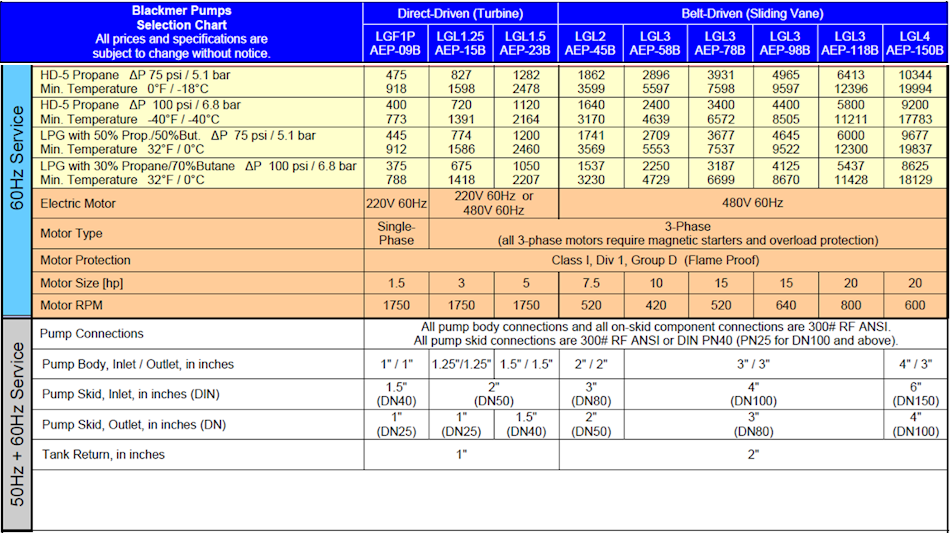

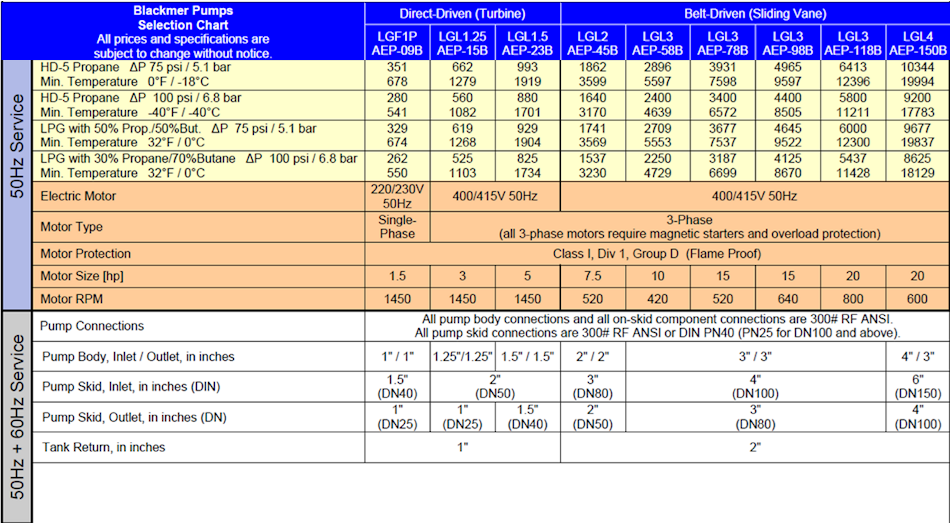

- Corken or Blackmer Pumps

- US or International Voltages

- Multiple starter options

- Integration with SNG System Controls

- Ex-proof Motors Class I, Div. 1, Group D (Flame-Proof)

LPG Transfer Pumps, as the name implies, are used to transfer LPG from the storage tanks to the vaporizer. In systems with Venturi LPG/air mixing systems, they are also responsible for maintaining the pressure needed for optimum and efficient function of the Venturi tubes.

All AES pump packages are mounted on steel skids, and are primed and painted. They are equipped with differential pressure regulator, constant pressure regulator, strainer, isolation valves, by-pass loops ("Summer-Bypass"), liquid filled pressure gauges, and all other components required for safe operation.

Smaller pumps up to 12 GPM are single phase AC 115/230V 50/60Hz service. Larger pumps are 3-phase AC 460V 60Hz or 400/415V 50Hz and require magnetic motor starters with overload protection. Pumps up to 18 GPM are direct-drive turbine type (electric motor directly coupled to pump). Larger pumps are belt driven, sliding-vane type.

A back pressure regulator provides stable delivery pressure by returning excess pump capacity to the storage tank.

All systems are supplied with an explosion proof motor to meet Class I, Div. 1, Group D (Flame-Proof) requirements.

Magnetic motor starters can be supplied either as a separate component, installed on the pump skid, or integrated with the system controls. If integrated with the system controls, a Start/Stop station at the pump skid is provided for local pump control.

All AES pump systems are available with either Corken or Blackmer pumps, and can be configured for various voltages and for 50 Hz or 60 Hz.

The purpose of Duplex Pump Systems is to provide maximum redundancy. They are therefore manufactured as individual pumps that only share a common skid. All bypass and isolation valves exist in duplicate. Each pump can be completely isolated so that maintenance and repair work on this pump does not affect the other pump, or the system availability.